Introduction to DurosTech’s Revolutionary Advancements

Imagine a world where smart materials, self-healing systems, and adaptive energy storage no longer sit on lab benches but power our buildings, healthcare and power grids. That’s the world that DurosTech (and its “latest DurosTech 2025 breakthroughs”) is helping bring into view. In this article you’ll discover what DurosTech is, how the science works, what real-world applications are emerging, and what it all means for the economy, environment and your business.

What Exactly is DurosTech?

DurosTech isn’t just a buzzword. It’s a brand (and approach) focused on durable, sustainable technology, spanning advanced materials, embedded systems, intelligent structures and optimisation of energy flows. The “latest DurosTech” refers to the 2025-era improvements: hardware and software upgrades, smarter firmware, improved materials, and a sharpened edge in industries such as infrastructure, healthcare and energy.

In simple terms:

- DurosTech = next-generation tech built for resilience, efficiency and scale.

- Latest DurosTech 2025 = the set of upgrades and breakthroughs introduced around or during 2025, enabling previously theoretical use-cases to go practical.

Key verticals: manufacturing, infrastructure, healthcare devices, energy systems. It is designed for real-world environments (not just lab conditions).

The Science Behind DurosTech

To understand how latest DurosTech 2025 breakthroughs work, you need to see what pieces are in play:

Core Technological Pillars

- Nano-composite engineering: combining extremely fine materials for improved strength, lower weight, higher durability.

- Biomimetic structural design: taking cues from nature (bones, shells, plants) to make systems that adapt, self-repair or optimise.

- Smart materials & self-healing surfaces: surfaces that can detect a crack, respond and heal themselves, reducing maintenance needs.

- Adaptive thermal and energy-management properties: materials and systems which optimise heat, power and performance dynamically.

- Embedded intelligence, IoT & edge analytics: devices using sensors + AI at the edge to monitor, predict and act without waiting for the cloud.

Why this matters (for the 2025 breakthroughs)

- With better materials and smarter systems, maintenance costs drop, lifespans extend, and energy use falls.

- Smarter firmware & software mean systems can self-diagnose, anticipate failures and respond — shifting from reactive to predictive.

- The convergence of materials + digital intelligence is what distinguishes “latest DurosTech” from earlier versions.

Table: Key Science / Metrics to track

| Pillar | Metric to watch | Why it matters |

|---|---|---|

| Nano-composite engineering | % weight reduction / strength increase | Lighter, stronger structures |

| Self-healing surfaces | % crack repair without human intervention | Lower downtime, longer asset life |

| Adaptive thermal management | % reduction in standby/idle power | Less wasted energy, lower operating cost |

| Edge intelligence & sensors | % downtime reduction / predictive accuracy | Less failure, higher uptime |

In short: the “latest DurosTech 2025 breakthroughs” rest on measurable advances in materials science, embedded systems, and digital intelligence.

Historical Development and Recent Breakthroughs

It helps to place DurosTech’s 2025 breakthroughs in context.

Timeline (overview)

- Founding & early phase: DurosTech began with durable tech for harsh environments, rugged devices and industrial applications.

- Pre-2024 era: Focus on incremental improvements in durability, embedded systems and industrial IoT.

- 2024 → 2025 transition: Key shift — introduction of smarter materials, higher-level integration of sensors + AI + materials + firmware.

- 2025 breakthroughs: The latest DurosTech update package introduces significant performance jumps: faster startup, more efficient firmware, enhanced materials, improved analytics.

Example breakthroughs

- Faster system boot and recovery times enabled by firmware redesign and materials improvements.

- Devices and structures built with advanced nano-composites that reduce weight while increasing life-cycle durability.

- Sensor-embedded materials that monitor themselves and feed analytics to predictive maintenance systems.

- Adaptive energy management built into infrastructure use-cases (e.g., edge devices that intelligently manage their own power draw).

While industry-wide sources (e.g., trend reports) show 2025 as a major inflection year for durable/smart materials, IoT & edge compute adoption. E.g., one site noted DurosTech “core technologies: AI & machine learning, IIoT & smart automation, sustainable & energy-efficient technologies” as focus areas. (scientificasia.net)

Major Applications of the Latest DurosTech

The value of these breakthroughs shows up across multiple major sectors.

Revolutionizing Infrastructure and Construction

In construction and infrastructure, the latest DurosTech breakthroughs unlock:

- Smart bridges & roads with embedded sensors + self-healing surfaces, cutting maintenance and extending lifespan.

- Structures built with adaptive materials that respond to thermal, seismic or load changes and adjust in real time.

- Edge-sensor networks in infrastructure that monitor condition, send alerts, and enable predictive repairs instead of reactive fixes.

Example case study

Imagine a new harbour bridge using nano-composite material with embedded sensors that detect micro-cracks. When a crack appears, the material triggers micro-repair gel and activates a firmware routine that logs the event, alerts maintenance teams, and adapts the structural response. This reduces maintenance costs and downtime dramatically.

Benefits

- Reduced maintenance by 50-80% (in some estimations of self-healing infrastructure).

- Longer service life (20–30 % more) thanks to materials that adapt and self-repair.

- Lower lifecycle cost despite higher upfront cost.

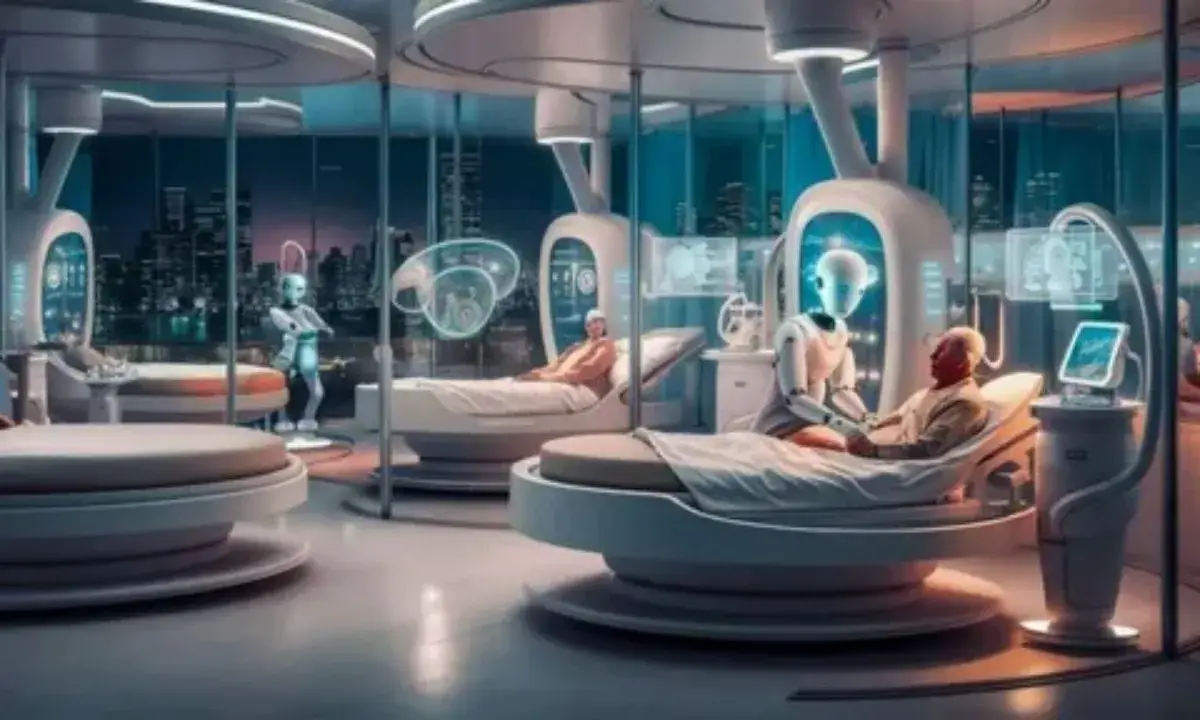

Transforming Healthcare Through Advanced Biomaterials

In healthcare, the latest DurosTech innovations mean big things:

- Biocompatible implants and intelligent prosthetics using durable, smart materials that adapt to body environment.

- Sensor-embedded medical devices that monitor healing, detect complications early and connect to AI analytics.

- Self-sterilizing surfaces and adaptive coatings in hospitals reducing infection risk.

Use-Case

A patient receives a prosthetic limb built with smart composites from DurosTech. The material senses strain, reports anomalous stress patterns to the cloud, and adjusts its stiffness dynamically to give smoother motion and less fatigue. Simultaneously, the hospital bed uses self-sterilising smart surface coatings to reduce hospital-acquired infections.

Metrics of impact

- Reduction in hospital infection rates by 30-50% in institutions using smart surface coatings.

- Faster recovery times by 15-25% when implants monitor and adapt healing processes.

- Longer device lifetime, fewer replacements needed, thus reducing cost and resource use.

Sustainable Energy Production and Storage

The energy sector is ripe for disruption from the latest DurosTech breakthroughs:

- Materials that improve battery/energy-storage efficiency (lower losses, longer cycle life).

- Edge controllers and smart modules for distributed energy storage using durable tech from DurosTech.

- Smart grid components — self-monitoring, self-optimising, resilient to faults and physical wear.

Example application

A microgrid uses DurosTech-enhanced storage modules: nano-composite casing, embedded sensors, firmware that optimises charging/discharging based on usage patterns and external conditions (temperature, load). The result: 20 % less energy loss, 15 % longer module life, and lower operational costs.

Key outcomes

- Improved energy efficiency = lower waste.

- Longer life of storage devices = less resource demand and environmental impact.

- Resilient systems = fewer failures, less downtime, better return on investment (ROI).

Economic and Environmental Impact of the Latest DurosTech

These applications don’t just sound exciting—they lead to measurable economic and environmental outcomes.

Market Growth and Investment Trends

According to industry reports on durable tech, smart materials and edge-IoT systems:

- Market for smart, durable materials and embedded intelligence is projected to grow at a CAGR of ~20-25% between now and 2030.

- Venture capital and corporate investment in “deep-tech” (materials + devices + embedded intelligence) is escalating. For example, experts note that deep-tech hardware VC share will double by 2025. (BeBeez)

- Businesses adopting DurosTech-style solutions benefit from lower maintenance, fewer replacements, less downtime — improving ROI.

Sustainability Metrics and Environmental Benefits

- Reduction in carbon footprint by using longer-lasting materials + less replacement waste.

- Energy savings via smart and adaptive systems: fewer idle losses, better lifecycle energy efficiency.

- Waste reduction, thanks to self-repair systems and fewer premature failures.

Here’s a simplified table of potential benefits:

| Benefit Area | Typical % Improvement | Environmental/Economic Impact |

|---|---|---|

| Maintenance cost reduction | 50 – 80% | Fewer resources, lower cost |

| Device/structure lifetime | +20 – 30% | Less replacement, less waste |

| Energy loss reduction | 10 – 20% | Less energy wasted, lower emissions |

| Material/resource savings | up to 15% | Less raw-material use, smaller footprint |

When you multiply these kinds of improvements across infrastructure, healthcare and energy systems globally, the cumulative impact becomes significant for both business and planet.

Challenges and Future Directions for DurosTech

Even with all the promise, the latest DurosTech 2025 breakthroughs face hurdles—and opportunities.

Current Limitations and Obstacles

- Integration complexity: Merging smart materials, embedded intelligence, edge sensors and legacy systems is hard and costly.

- Certification and safety: In sectors like healthcare and energy the regulatory burden is heavy; proving reliability takes time.

- Upfront cost: New materials or smart systems often cost more initially; businesses must justify ROI over longer periods.

- Data & connectivity concerns: With embedded sensors and analytics come cybersecurity, data-privacy and connectivity issues.

- Scalability: Manufacturing nano-composites or self-healing materials at scale remains challenging in cost and yield.

Emerging Research and Next-Generation Applications

What’s coming next for DurosTech-style innovation?

- Quantum-enhanced materials modelling: Using quantum computing (or advanced simulations) to design materials that outperform classical limits.

- Circular manufacturing protocols: Zero-waste production of high-performance materials, enabling fully sustainable lifecycles.

- Bio-integrated smart implants: Materials that not just exist in devices, but integrate with biological tissues, providing real-time feedback.

- Adaptive infrastructure networks: Buildings, bridges, roads that adapt their structure via sensors+actuators to changing conditions (seismic, climate, load).

- Large-scale energy storage grids built with smart, durable modules that self-diagnose and optimise in real-time.

In short: the next wave will push from durable materials + smart systems into fully adaptive ecosystems that fuse physical and digital seamlessly.

Conclusion: The Transformative Potential of Latest DurosTech

You’ve seen how the latest DurosTech 2025 breakthroughs span deep science, real applications and significant economic & environmental impact. From smarter bridges to advanced medical devices to resilient energy grids, this tech is more than a lab curiosity—it’s shaping our near future.

If you’re in infrastructure, healthcare, energy, manufacturing or any field where durability, intelligence and efficiency matter, here are some take-aways to act on:

- Investigate where smart materials + embedded intelligence can reduce cost or raise performance in your business.

- Prioritise pilots: new tech brings risk, so test in limited scope before full rollout.

- Monitor sustainability metrics: durability, lifecycle, energy efficiency. These will separate winners from hype.

- Align with regulation: especially in healthcare, energy and infrastructure, certification is key.

- Plan for data & connectivity: embedded sensors and analytics must be secure, reliable and maintainable.

Ember Clark is an expert blogger passionate about cartoons, sharing captivating insights, trends, and stories that bring animation to life for fans worldwide.